Case Studies

Real-world Industrial IoT deployments demonstrating reliability, scalability, and impact.

Oil & Gas — Corrosion Monitoring

Critical oil and gas pipeline infrastructure required continuous monitoring to detect corrosion and degradation under harsh environmental conditions.

Hexitronics deployed industrial-grade sensors integrated with RS-485 gateways and cloud dashboards to capture corrosion parameters in real time.

Enabled early anomaly detection, reduced manual inspections, and improved asset life-cycle planning.

Municipal Infrastructure — Fire Hydrant Monitoring

Municipal fire hydrant networks lacked real-time visibility into availability and pressure readiness.

Smart sensor retrofitting with IoT gateways and centralized dashboards was implemented across multiple locations.

Improved emergency preparedness, faster maintenance response, and centralized monitoring for authorities.

Energy & Utilities — AMR Retrofit

Industrial facilities relied on manual meter readings for energy and water consumption, leading to delays and inaccuracies.

Legacy meters were retrofitted with AMR devices enabling automated data acquisition and secure transmission.

Achieved accurate billing data, operational transparency, and data-driven energy optimization.

Cold Supply Chain Temperature Monitoring in Ice Cream Distribution

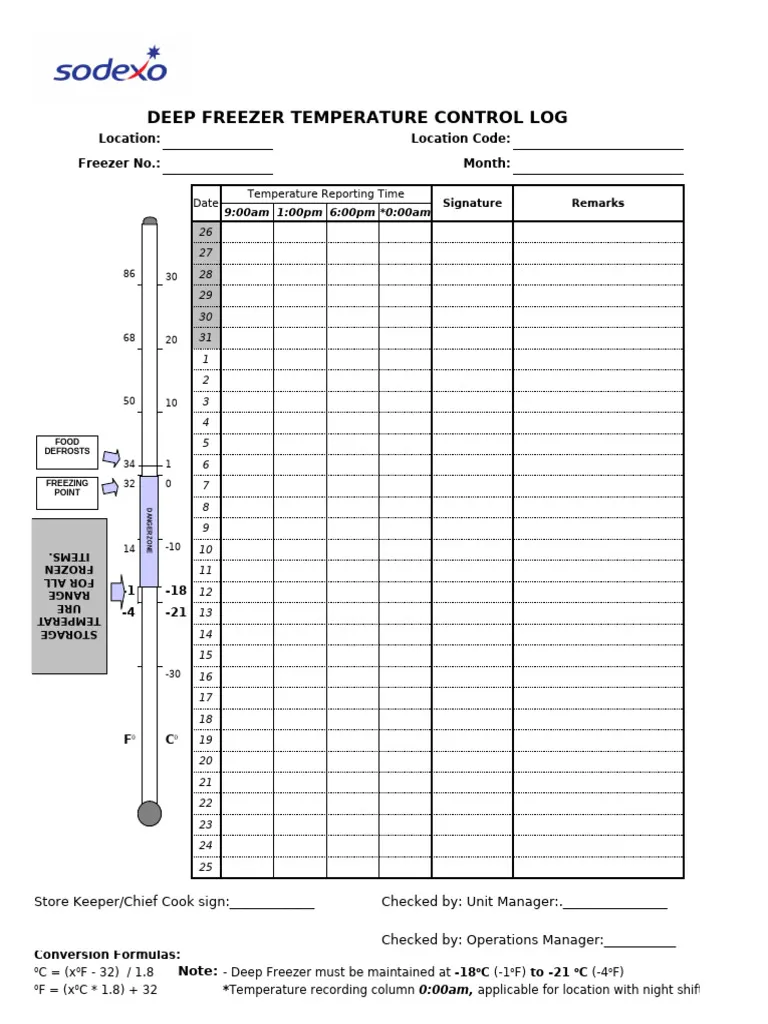

Left: Retail deep freezer used for ice cream storage. Right: Traditional manual temperature log used before IoT-based monitoring.

Industry: Food & Beverage – Ice Cream Distribution

Application: Deep Freezer Temperature Monitoring at Retail Outlets

Location: Multi-city deployment (India)

Timeframe: January 2022

Nature: Experience-based deployment (NDA compliant)

Background

Ice cream quality is extremely sensitive to temperature stability. Even short and repeated temperature excursions inside deep freezers can lead to partial melting, refreezing, texture degradation, and loss of product consistency. These failures are often invisible but result in customer complaints and commercial disputes.

Problem Statement

A large food and beverage brand operating more than 150 cloud kitchens and retail outlets across India was receiving frequent complaints from retail partners regarding poor ice cream quality. Retailers often cited quality degradation as a reason for reduced payments.

While manufacturing and upstream cold storage were compliant, there was no objective data to determine where the quality degradation was actually occurring.

Solution Deployed

Hexitronics implemented an IoT-based temperature monitoring system inside deep freezers installed at retail outlets. Approximately 50 IoT devices were deployed with temperature sensors embedded directly inside the freezers.

K-type thermocouples were selected to reliably monitor negative temperatures down to –30 °C. The primary objective was continuous temperature visibility rather than advanced automation.

Sensors & Data

- K-type thermocouple temperature sensors

- Continuous temperature logging

- Time-stamped temperature trend graphs

- Web-based dashboard visualization

Key Observations from Data

After one month of operation, the temperature data revealed sharp and repeated temperature spikes. These spikes were clearly correlated with door opening events of the deep freezers.

The data made it possible to identify how frequently the freezer doors were opened, how long they remained open, and the time-of-day patterns of usage.

Operational Intervention

The brand owner conducted a joint meeting with retail outlet partners and presented the temperature graphs on a web dashboard. The data was used to clearly explain how frequent door openings caused temperature instability and product quality degradation.

It was reiterated that deep freezers are not meant for frequent access and should not be used as regular refrigerators. A separate refrigerator was recommended for daily sales, while deep freezers should be opened only one to three times per day.

Business Impact

- Root cause of quality degradation conclusively identified

- Retail partners acknowledged operational lapses

- Payment disputes resolved using objective temperature data

- Outstanding dues successfully recovered

- Improved handling discipline across retail outlets

Key Learning

This deployment demonstrated that IoT is not only a monitoring tool but also a powerful mechanism for accountability, behavior correction, and dispute resolution. In this case, IoT converted an operational assumption into verifiable proof.

Status: Successfully deployed (experience-based case study)